Machine Operation

Place the empty bottles on the holders, the holders would push the bottle upwards while the star wheel is rotating, due to vacuum the bottle(s) would get filled and the excess perfume would automatically be thrown in the overflow jar.

PERFUME TRANSFER PUMP OPERATION: When the machine is started, there is a level Switch Provided in the perfume filling tank, which gives an indication to the perfume transfer pump which sucks the perfume from the storage vessel and transfer it into the perfume filling tank, when the filling tank is filled to the level, again the switch gives indication and stops the transferring process and vice versa.

NO BOTTLE NO FILLING. MACHINE OPEERATING IS VERY EASY.

Salient Features

- Vaccumetric filling system.

- Flame-proof motor for vacuum pump & main drive.

- Speed variable system by mechanical By Delta operation (for safety purpose).

- Electronic flame proof liquid level sensor provided.

- Perfume transfer pump not required.

- Hardchrom plated camps.

- Tefflon NRV/seal & other required parts.

- Accurate level filling.

- All contact parts made out of SS 304 L materials.

- Table stand, top, covers made out of SS 304 material.

- Auto overflows perfume transfer in filling line.

Technical Specifications

| Model | WPM – RPF 45 |

| Maximum filling capacity | 225ml |

| Minimum filling capacity | 10ml |

| No. of filling head | 9 Head |

| Main drive geared motor | 0.5 HP FLP |

| Vacuum pump | 0.5 HP FLP / 150 LPM / |

| Approx. machine dimension | 800mm W x 850mm L x 1800 H |

| Approx. production/ capacity (by changing filling syringes) |

10 ml to 100 ml : 60to 55 BPM , 100 ml to 200 ml : 40 to 35 BPM |

| Speed | Variable By Delta |

| Manpower required | 1 or 2 people |

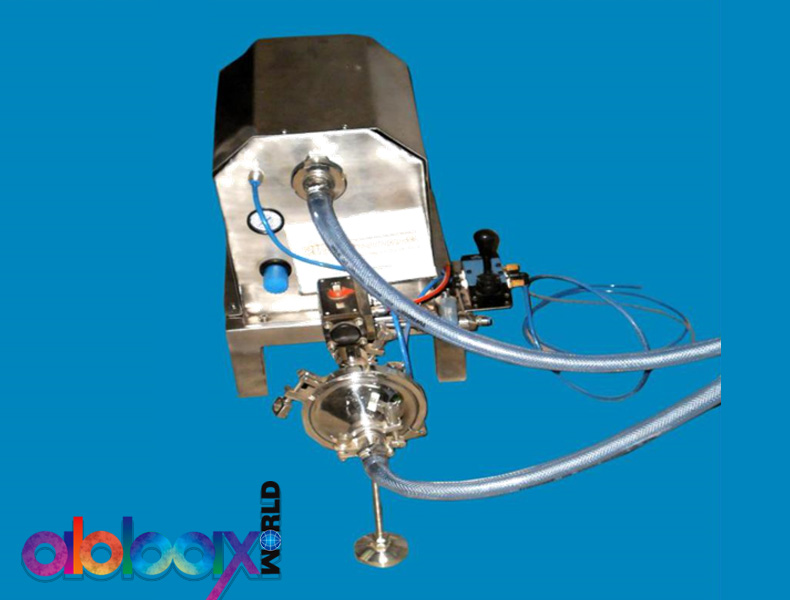

Machine Operation

It is type of with fitter perfume and transfer the perfume from tank to the filling machine.

Technical Specifications

| Approx. dimension (L x H x W) | 420 x 900 x 410 (mm) |

| Type | Double Diaphragm Pneumatically Operated |

| Included Accessories | 1) Automatic Pneumatic Actuator Valve 2) Nitrogen Flush Actuated Valve. 3) Conical Filter 4) Regulator 5) Pressure Guage Festo 6) SS 304 Stand & Cover. |

| Air Required | 4-6 Kg Bar (Adjustable By Regular) |

| Pump Size | 15mm |

| Connection | 15mm Din Hose Nipple(Input &Output) |

| Liquid Output Capacity | 200-700 Mph Depending On Type Of Liquid |

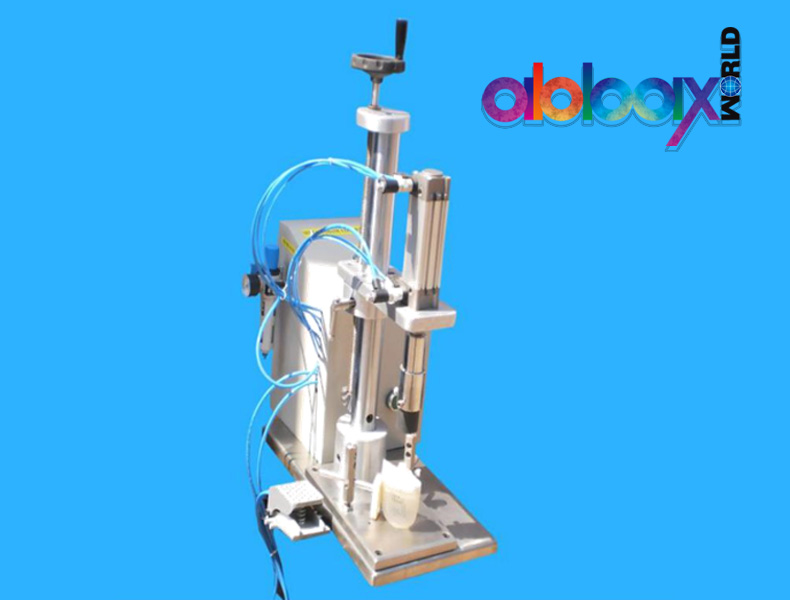

Machine Operation

Pick up the perfume filled bottle from conveyor manually & place on the platform of crimping machine. Crimping head will come down & collet will crimp the aluminum cap. Remove the crimping bottle.

Salient Features

- 100 % pneumatically operated machine.

- FRL provided with the machine.

- Festo make heavy duty pneumatic cylinder

- Very each operation and change parts.

- Replacing crimping collet is a very easy job.

- S.S. covering of main machine body.

- Machine can be mounted on top of conveyor by S.S. platform or with the powder coated stand.

- Automatic pressure adjust of pneumatic operation as per require.

Technical Specifications

| MODEL | WPM-PCR-01 |

| Approx dimension (without stand) | 325 X750 X 650 |

| Air require | 80 PCS / 6 kg/Sq. Cm (8 Bar) |

| Number of crimping head | 1 No |

| Number of Pneumatic Cylinder | 2 Nos |

| Operator Require | 1person |

| Production | Up to 35 BPM (As per operator Efficiency) |

Machine Operation

Pick up the perfume filled bottle from conveyor manually & place on the platform of crimping machine. Crimping head will come down & collet will crimp the aluminum cap. Remove the crimping bottle.

Salient Features

- 100 % pneumatically operated machine.

- FRL provided with the machine.

- Festo make heavy duty pneumatic cylinder

- Very each operation and change parts.

- Replacing crimping collet is a very easy job.

- S.S. covering of main machine body.

- Machine can be mounted on top of conveyor by S.S. platform or with the powder coated stand.

- Automatic pressure adjust of pneumatic operation as per require.

Technical Specifications

| MODEL | WPM-PCR-01 |

| Approx dimension (without stand) | 325 X750 X 650 |

| Air require | 80 PCS / 6 kg/Sq. Cm (8 Bar) |

| Number of crimping head | 1 No |

| Number of Pneumatic Cylinder | 2 Nos |

| Operator Require | 1person |

| Production | Up to 35 BPM (As per operator Efficiency) |

Salient Features

- Top SS304 1.6 mm thickness with waterproof plywood vibration alignment.

- Adjustable height 50 mm

- Stand ss304 heavy duty pipe With full matt finish.

- Tabletop is full dismantled Type.

- Speed of conveyor is variable by imported drive with SS304 Control panel box, push button (On/Off).

- A.C worm reduction gear motor-bonfiglioli make.

- Assembly and dismantling very easy.

- Imported belt pvc belt 2 mm thick green conveyor belt.

Technical Specifications

| Size | 25 ft |

| Table Top Width | 950 mm |

| Adjustable Height 60 mm | 750 mm |

| Belt (Width) | 245 mm |

| Motor ( Hindustan Make) | 0.5 hp |

| Speed of Belt | 1-6 mtr |

Machine Operation

Machine fully manually operated. Take totally filled perfume bottle and Place bottle inside the machine glass tube and lock the tube and open the value. Keep the bottle on tissue paper. Lick will be get lick on tissue paper.

Salient Features

- Only one operator required.

- Total Pneumatic material of Festo Make.

- Machine made of SS 304L

Technical Specifications

| MODELS | 01 |

| Production capacity | 35 BPM |

| Approx machine dimension | 400 l X 250 X 5 mm Thick |

| Air required | 80 PSI / 4 Kg cm |

| FRL | ¼ BSP |

| Vacuum Generator | 3/8 BSP |

| Pressure Ganged | 1 NO |

Salient Features

- SS304 Rollers with smooth rotation.

- M.S. powder coated heavy duty stand.

- Adjustable inclination height.

Technical Specifications

| Maximum width | 550mm |

| Maximum length | 2000mm |

| Height | 620-800mm |

| Roll diameter | 32mm |

| No. of Rollers | 25-30pcs. |

Industrial Catagories

perfume filling machinery, perfume filling machine, perfume filling machine manufacturers, automatic perfume filling machine, perfume filling and crimping machine, semi automatic perfume filling machine, perfume bottle filling machine, filling machine for perfume, vacuum filling machine for perfume, pocket perfume filling machine, rotary perfume filling machine, small perfume filling machine, vacuum perfume filling machine